Sometimes you need to trench or dig near or around buried electric lines to install cable, pipes, or fence posts, and a machine cannot perform the delicate maneuvering required.

Insulated shovels are created for use around these power lines or other areas with a risk of electrocution. The insulated shovel has an insulated socket, shaft and handle to protect the user if they come in contact with a live wire. In addition, the protective coating helps avoid injury and improves safety while digging around power lines.

Table of Contents

Effective Insulators Against Electricity

What makes a material an insulator is its resistance to the flow of electrons. Electrons are negatively charged particles that flow through materials to create an electric current. The higher the resistance, the more difficult it is for electrons to flow and the better the material’s insulating properties.

The best insulator against electricity is a material that does not conduct electricity. You can accomplish this by using a material that is not a metal or by using a non-conducting coating on a metal. Many insulating materials are available, so choosing the right one depends on the specific application. For example, some insulators are better at resisting high temperatures or providing mechanical strength.

ThoughtCo. lists some common insulating materials including:

- Rubber is a good insulator in many electrical applications such as wiring and cables.

- Glass, porcelain and ceramic are good insulators for insulating electrical components against high temperatures.

- Fiberglass is an excellent insulator and is often used in high-temperature applications.

- Plastic, polymer coating or polypropylene is another common insulator. It can be injection moulded into complex shapes for various electrical applications.

Which Type Of Insulation Will Protect A Person

The best type of insulation for protecting a person from electricity is rubber. Rubber does not conduct electricity, so it will prevent electrical current from passing through the body.

Another option is polypropylene which is a more rigid material. Rubber wears quicker than polypropylene as rubber is a softer material, so it is more susceptible to wear and tear. However, both materials will eventually wear out over time.

How The Shovel Is Insulated

The shovel blade is not what is insulated against electricity; it is the socket, shaft and handle components of the shovel that are protected. Therefore, if the blade of the shovel becomes charged, that charge will not travel up the socket, shaft and handle and into your body, keeping you safe.

The shaft of these shovels is a solid fibreglass core that is then further coated with layers of polypropylene. Finally, polypropylene, also known as plastic or polymer coating, is also placed over the shovel’s socket. The socket is where the shovel head or blade attaches to the shaft and handle.

Polypropylene has a high resistance to the flow of electrons, which makes it an ideal material for insulated shovels as it will protect you against electrocution. Polypropylene is also lightweight, durable and has a low moisture absorption rate, meaning that insulated shovels made with this type of insulation will last longer and provide better protection.

When purchasing an insulated shovel, ensure the insulation layers are intact and not peeling or dry rotted, decreasing the shovel’s effectiveness. Also, make sure you choose a shovel with the best socket type for the job to ensure you have the best possible protection against electrical hazards.

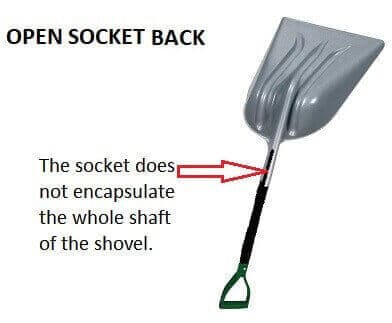

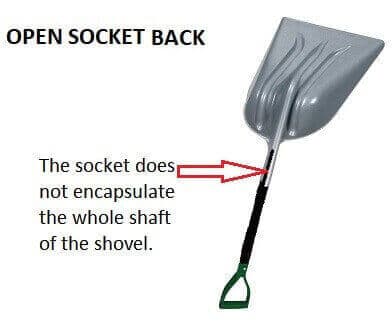

Types Of Sockets On A Shovel

The socket type on an insulated shovel is often overlooked as a safety component. You can find three types of sockets on a shovel:

1. An open socket is found on shovels used for lighter work, such as shovelling snow, sand or gravel.

2. A solid socket is created when the blade and socket are forged into one piece. The socket is then attached to the shaft. A solid collar is very strong, and a shovel created with this collar style will be long-lasting. In addition, this type of collar is the strongest and most reliable of all three sockets.

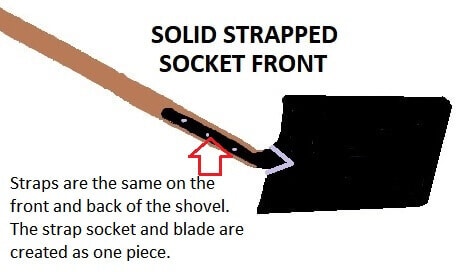

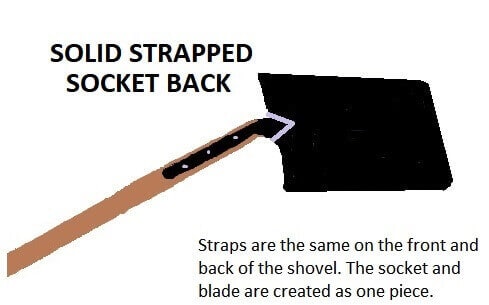

3. A solid strapped socket is also forged into one piece, just as the solid socket. However, in a strapped socket, the forging process creates two metal strips that extend from the blade, which are then riveted to the shaft. A shovel with a strapped socket gives substantial support to the shaft, and you find this type of socket on shovels used for medium to heavy-duty work.

Determining which type of socket is best for an insulated shovel will be determined by your needs. As an open socket is for lighter work, this style or socket would not help create a trench or dig in clay or rocky soils, which is usually the case in most situations.

This leaves the choice between a solid socket and a solid strapped socket. The solid socket has the potential to have the outer layer of insulation peel or dry out, which could then create a decreased barrier to you against potential injury. On the other hand, this type of collar is the strongest, and if you need the job done quickly, this may be the type of socket to choose.

The solid strapped socket will provide more protection against currents as there is less metal that could become exposed. In addition, polypropylene adheres better to fibreglass than metal, and with a strapped socket, there is more of the fibreglass handle exposed, meaning that the outer layer of insulation will be less likely to peel or dry out.

The Type Of Handle On An Insulated Shovel

The handle is an integral part of the shovel as it is what you hold on to. When looking for an insulated shovel, choose one with a plastic or fibreglass handle. Wood handles are not recommended though wood is not a great conductor of electricity; they can conduct electricity.

If the handle does become wet, it is essential to dry it off as soon as possible. If the handle is left wet, it could create a path for electrical current to travel through the body if the blade of the shovel comes in contact with an electrical source, as electricity can jump from the shovel blade to the wet location despite the coatings on the shaft and handle.

It is also essential to check the condition of the handle regularly. If there are any cracks or breaks in the handle, replace it immediately. A broken handle can create a path for electrical current to travel through the body if the shovel’s blade comes in contact with an electrical source.

Safety Considerations When Shoveling Around Electricity

When shovelling around electricity, it is crucial to take the following safety precautions:

1. Wear insulating gloves and rubber-soled shoes.

2. Avoid touching any exposed metal on the shovel.

3. Do not allow the blade of the shovel to come into contact with any wires or power lines.

4. Use extra caution when shovelling around energized equipment.

5. If you must dig near energized power lines, always call your local utility company to have the power lines marked before you begin work.

6. When storing your insulated shovel, keep it in a dry location, as moisture can damage the handle and reduce the effectiveness of the insulation.

7. Always check your shovel thoroughly before each use to ensure that it is in good condition and will provide you with the best possible protection.

Following these safety precautions can minimize the risk of electrocution when shovelling around electricity.

Final Thoughts

An insulated shovel is a necessity if you are going to be working around electricity. The right type of shovel will provide you with the best possible protection against electrocution. When choosing an insulated shovel, select one made from polypropylene, as this material has the highest resistance to the flow of electrons. Also, check that the insulation layers are intact and in good condition before each use.