Wear resistance is crucial in determining a rope’s longevity and effectiveness for various applications. A highly wear-resistant rope is essential for tasks that require durability, as it ensures reliability and safety.

Table of Contents

Different Types of Wear-Resistant Ropes

By understanding the characteristics of different rope materials and their resistance to wear and tear, you can confidently select a rope that offers the best balance of strength, durability, and suitability for your intended application. As a result, you can ensure the efficiency and longevity of your chosen rope, ultimately leading to your project’s overall success.

Nylon Rope

Nylon ropes are recognized for their exceptional strength and durability. They are highly resistant to wear, rot, and mold, making them popular for various applications. One notable characteristic of nylon is its ability to stretch under load, which can be helpful or unhelpful, depending on the specific use. Due to their high abrasion resistance and overall strength, nylon ropes are well-suited for applications such as towing and pulleys.

Polyester Rope

Like nylon, polyester ropes exhibit strong wear resistance and are less prone to rot and mildew. Unlike nylon, polyester ropes have low stretch capabilities, making them ideal for situations where less elasticity is desired. This attribute is handy when working with heavy loads or applications requiring precise rope tension control. Polyester ropes also possess excellent UV resistance, which helps maintain their durability when exposed to sunlight for extended periods.

Polypropylene Rope

Polypropylene ropes are lightweight and affordable, with good wear resistance and floating capabilities. They are resistant to mould, mildew, and various chemicals, making them suitable for wet environments. However, polypropylene ropes are less intense than nylon and polyester ropes and more susceptible to UV damage. These ropes are commonly employed in general-purpose applications or as a cost-effective alternative when higher-strength materials like nylon or polyester are unnecessary.

Manila Rope

Manila ropes, made from natural fibres, fall short when wearing resistance compared to their synthetic counterparts. While manila ropes possess decent strength and have a traditional aesthetic, they are more vulnerable to rot, mould, and deterioration from environmental factors. Moreover, they lack the advanced UV resistance and abrasion-resistance properties that synthetic ropes like nylon, polyester, and polypropylene offer. As a result, manila ropes are usually chosen for decorative or light-duty applications rather than heavy-duty or highly abrasive tasks.

Factors Affecting Durability Of Wear Resistant Rope

Material: The choice of material is crucial in determining rope durability. Different materials possess distinct properties that affect their wear resistance and other factors related to durability. For instance:

- Fibre: Synthetic fibres like nylon, polyester, and polypropylene provide good strength, abrasion resistance, and flexibility. However, these may not be as rot-resistant as natural fibres.

- Steel wire: Known for their superior tensile strength and wear resistance, steel wire ropes are commonly used in demanding applications. However, they may be more susceptible to corrosion.

UV and Chemical Resistance: Exposure to sunlight, chemicals, and various environmental factors can significantly impact a rope’s durability:

- Sunlight: Direct exposure to the sun’s UV rays can degrade some materials, such as synthetic fibres, leading to loss of strength and wear resistance over time.

- Chemicals: Some rope materials are more resistant to damage from exposure to chemicals, such as oils, acids, and bases. Selecting a rope with proper chemical resistance is essential for improved durability.

- UV resistance: Ropes with UV resistance can better withstand the harmful effects of sunlight and maintain their strength longer.

Strength and Tensile Properties: Various tensile properties, including strength and resistance to fatigue, also determine the durability of a rope:

- Strength: The ability of a rope to bear the stress applied to it without breaking is a vital factor in wear resistance. A rope with high tensile strength is likely to be more durable.

- Tow: A rope’s towing capacity can also affect its durability. Ropes designed for high-capacity towing should be manufactured from materials with high tensile strength to ensure long-lasting performance.

- Abrasion-resistant: A rope’s ability to resist wear and tear caused by friction is crucial for enhancing its longevity.

Applications of Wear-Resistant Ropes

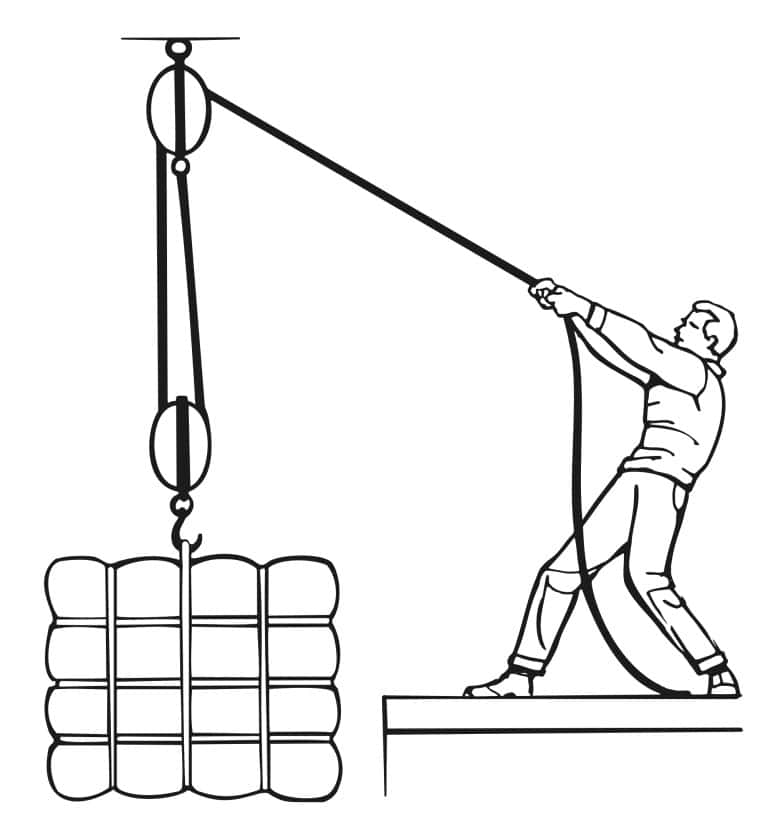

Wear-resistant ropes are suitable for rigorous land-based applications such as rigging, farming, and landscaping. Due to their excellent tensile, torsion, and bending resistance properties are commonly used in hoisting machinery, elevators, and heavy-load transportation in industrial settings. In farming and landscaping, wear-resistant ropes can secure loads, create rope ladders, and support pulley systems.

Wear-resistant ropes are also suitable for recreational applications, such as creating swimming lanes and exercise equipment, where longevity and tension maintenance are crucial.

In the marine environment, wear-resistant ropes exhibit remarkable resilience against harsh conditions, such as exposure to saltwater, high temperatures, and constant friction. Due to their flexibility and strength, they are widely used in anchor lines, moorings, and sailing systems.

These ropes’ high wear resistance ensures long lasting performance in demanding applications, making them the go to choice for marine professionals.

Beyond their industrial and marine applications, wear-resistant ropes are used in home decor, crafts, and various DIY projects. Their durability and appearance make them perfect for gardening, where they can be employed to construct plant supports and trellises.

Wear-resistant ropes can be cleverly integrated into various elements in home decor, such as furniture, wall hangings, or lighting fixtures. They are also ideal for crafting hobbies and DIY projects, offering a sturdy yet flexible medium for creativity.

Final Thoughts

By understanding the characteristics of different rope materials and their resistance to wear and tear, you can confidently select a rope that offers the best balance of strength, durability, and suitability for its intended application.

Frequently Asked Questions

Which ropes have the highest tensile strength?

Ropes made from high-performance materials like Dyneema, Kevlar, and Nylon have excellent tensile strength. These synthetic ropes are known for their exceptional strength-to-weight ratios and resistance to wear, abrasion, and chemicals. Choosing ropes with high tensile strength can give you a sense of security and confidence in their performance.

What types of ropes are commonly used in marine applications?

Polyester and polypropylene ropes are typical for marine applications as they resist moisture, UV rays, and abrasion. Both materials can float, and polypropylene, in particular, is valued for its lightweight nature, making it a popular choice for water-related activities.

Which ropes offer the best resistance to rot and moisture?

Thanks to their synthetic nature, polyester ropes offer the best resistance to rot and moisture. They are also resistant to water damage and UV rays, helping to protect them from becoming brittle and weak.