People use many varied materials to make rope, but some are stronger than others and have more applications. The more durable rope varieties include Kevlar and nylon rope. Weaker materials like cotton and polypropylene are much less accommodating.

The material that comprises a rope and the ropes application truly determines the strength or weakness of rope. Therefore, to determine which type of rope is the strongest or weakest, we must look closely at each of these factors.

We will review the top six rope fiber choices Kevlar, UHMWPE – Ultra High Molecular Weight Polyethylene, Nylon, Cotton, Polypropylene, Manila Rope

Table of Contents

Review Of The Strongest and Weakest Types Of Rope

1. Kevlar Rope

Kevlar is best known for its military applications and use in bulletproof materials. What you may not know, however, is that Kevlar is also used to create rope. One of the most durable materials for rope construction.

Kevlar is stronger than steel in a pound-by-pound comparison.

Kevlar also has various other desirable characteristics that make it ideal for multiple industries and applications that include:

- Breaking Tenacity When Dry: 18-26.5 (grams/denier)

- High buoyancy.

- Water-resistant fibers.

- Resistant to mildew and rot.

- Resistant to oil and gas.

- Good cut resistance.

- Acid and Alkali resistance.

Most commonly, professionals prefer Kevlar rope for architectural projects, engineering applications, underwater applications, and environments where extreme temperature changes are likely.

Kevlar rope even has applications in the space program – engineers used it on the Mars Pathfinder!!

2. UHMWPE – Ultra High Molecular Weight Polyethylene

Spectra Ultra-High molecular weight polyethylene (UHMWPE) is best known for marine and fishing applications, and architects and engineers also use it as a lighter alternative for steel cables.

This rope has the highest strength rope fiber and is stronger than steel and Kevlar. Spectra Ultra-High molecular weight polyethylene (UHMWPE) also has several other desirable characteristics that include –

- Breaking Tenacity When Dry: 30.0 (grams/denier)

- Fair shock-load absorption.

- High buoyancy.

- Water-resistant fibers.

- Resistant to mildew and rot.

- Resistant to oil and gas.

- Good cut resistance.

- Acid and Alkali resistance.

- Can be stored wet or dry.

UHMWPE is used most commonly in large marine applications, offshore oil and gas industries, lifting slings, and utility stringing.

3. Nylon Rope

Nylon is a very diverse material, and nylon rope is just as versatile with applications across about every industry. Nylon rope is not as strong as UHMWPE or Kevlar rope, but still has some great qualities that include:

- Breaking Tenacity When Dry: 7.0-9.5 (grams/denier)

- Excellent shock-load absorption ability.

- No Buoyancy.

- Moderate extension under a sustained load.

- Low water absorption fibers.

- Good UV light resistance.

- Rot and mildew resistance.

- Can be stored wet or dry.

- Has a high external abrasion resistance and excellent internal abrasion resistance.

- High melting point.

- High alkali resistance.

- Oil and gas resistance.

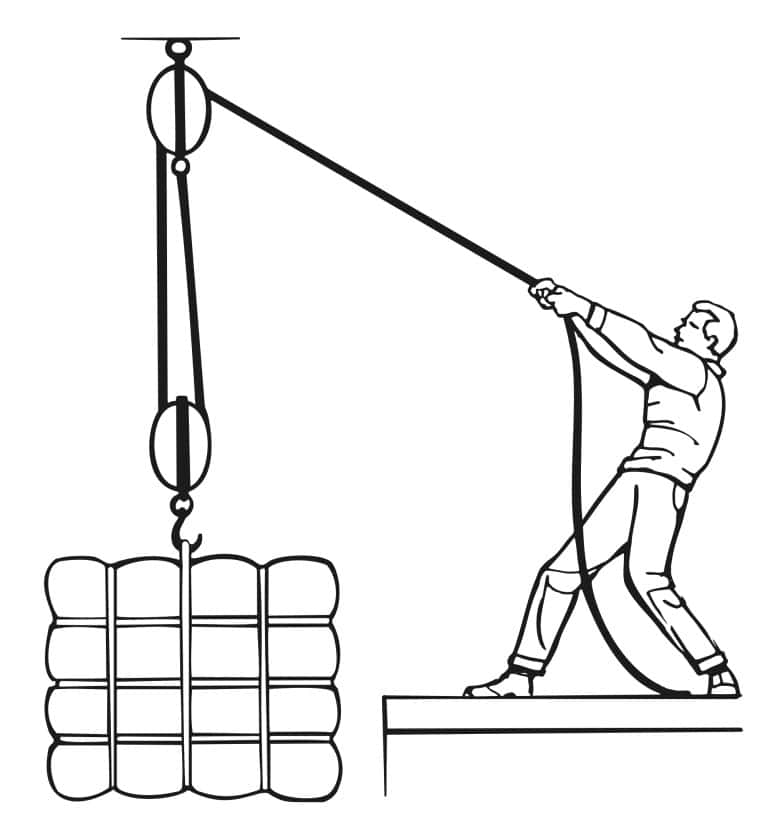

Most commonly, engineers use nylon rope for winches, pulley systems, towing systems, lifting operations, and any job where the fibers must absorb shock.

4. Cotton Rope

The use of cotton rope has many applications; however, ensure the usage does not include a situation where the rope must support any weight.

Cotton is the weakest material for rope construction and is primarily utilized in hobby and creative applications such as cooking, home décor, crafts, gardening, and agricultural applications.

Unlike other types of rope, the cotton rope has very few desirable properties:

- Breaking Tenacity When Dry: 2.0-3.0 (grams/denier)

- Poor shock load ability.

- Low extension under sustained load.

- High water absorbency.

- Good UV resistance.

- Poor mildew and rot resistance.

- It can only be dry stored.

- Poor abrasion resistance.

- Poor acid resistance.

- Fair alkaline resistance.

- Poor gas and oil resistance.

Although it has few applications, cotton rope is softer when held, making it much more flexible and easier to tie in knots.

Crafters also prefer cotton rope since it is highly absorbent, making dying easier.

5. Polypropylene Rope

Polypropylene is a synthetic material commonly used across industries because it performs well in wet and dry environments.

Although not the most durable rope option as it is one of the weakest ropes, polypropylene is preferable in marine applications because it floats and does not absorb water.

When it comes to other characteristics, polypropylene is a middle of the road rope option with a mixed bag of properties, including:

- Breaking Tenacity When Dry: 6.5 (grams/denier)

- Poor shock load ability.

- Low extension under sustained load.

- Low water absorbency.

- Good UV resistance.

- Has poor mildew and rot resistance.

- It can only be dry stored.

- Poor abrasion resistance.

- Poor acid resistance.

- Fair alkaline resistance.

- Poor gas and oil resistance.

Polypropylene rope is not only suited to marine or water use; however, it is also available in a spectrum of colors which makes this a good option for marking boundaries for outdoor events or gatherings.

6. Manila Rope

Second to cotton, manila is one of the weakest rope fiber choices, but it is the fiber most people think of when they visualize rope.

Manila rope can withstand a good amount of tension without snapping while also being flexible. However, the manila rope is another mixed bag when it comes to fiber qualities as it is:

- Breaking Tenacity When Dry: 5.0–6.0 (grams/denier)

- Stronger when wet than when dry.

- Has poor shock load absorption ability.

- No buoyancy.

- Low extension under sustained load.

- High water absorption.

- Good UV resistance.

- Poor mildew and rot resistance.

- Must be stored in a dry environment.

- Fair abrasion resistance.

- Low acid and alkali resistance.

- Poor gas and oil resistance.

Engineers use manila rope in applications that are regularly under strain, particularly when exposed to outdoor elements.

Manila is also the rope of choice for gymnasiums because, unlike synthetic fibers, there is no snapback when the holder releases the manila rope.

ROPE STRENGTH CHART

| ROPE | BREAKING TENACITY WHEN DRY GRAMS/DENIER | BEST USE |

| COTTON | 2.0-3.0 | Hobby and creative applications |

| MANILA | 5.0-6.0 | outdoor applications under strain |

| POLYPROPYLENE | 6.5 | water applications |

| NYLON | 7.0-9.5 | jobs where the fibers must absorb shock – pulleys, towing, winches |

| KEVLAR | 18-26.5 | extreme temperature application |

| UHMWPE | 30 | marine applications |

Summary

For the most part, the strongest and weakest rope materials depend on the application of the rope.

However, when it comes down to answering which rope is strongest, UHMWPE – Ultra High Molecular Weight Polyethylene rope is the strongest rope option.

As for the weakest rope? That honor belongs to the cotton rope as it is the least functional for multiple applications.