When it comes to ropes, there are two main types – kinetic rope and traditional rope. The name kinetic rope comes from the fact that kinetic energy is stored within the rope when it is under tension, providing an extra layer of strength.

Table of Contents

What Is Kinetic Rope

Kinetic ropes are created by blending synthetic fibres such as nylon, polyester, and Kevlar that provide superior strength and flexibility. As you might know, the kinetic rope was made in the early 1900s, and in the 1970s, researchers observed how ropes move during climbing and rappelling and realized a kinetic rope would work best, and these ropes gained popularity in the 1990s.

Kinetic ropes react when pulled, generating energy to lift or pull objects and are made from two shells, an inner and an outer, of nylon fibres twisted into a cord. This rope is also known as active, sport, snatch or yanker rope as it can stretch with various load rates, but it keeps its shape and strength over time. It is flexible, lightweight, and has high tensile strength and anti-slip properties, meaning they are easier to grasp and hold on to, making them safer to use than traditional ropes.

They offer better protection against UV radiation and moisture, making them ideal for outdoor use. Additionally, kinetic ropes often bounce back into shape faster than traditional ropes, so they’re less likely to tangle or knot up in the middle of a climb or descent.

Main Difference Between Kinetic And Traditional Ropes

When it comes to ropes, there are two main types – kinetic and traditional. Traditional ropes have value in various applications but tend to be less energetic and durable. Unlike traditional ropes, a kinetic rope can handle sudden changes in tension without stretching or breaking, making it ideal for emergencies where quick adjustments may be needed. Kinetic ropes are also more resistant to rot, mildew and saltwater corrosion than other types of rope, making them great for maritime applications.

A traditional rope is typically made from natural fibres like hemp or manila, which are strong but tend to stretch and break when put under pressure over time and is not as resistant to weathering or marine environments. Ultimately, kinetic ropes provide superior strength and flexibility while still being lightweight enough to carry with you wherever you need it.

Eleven Uses Of Kinetic Rope

A kinetic rope is an excellent choice for emergency preparedness, rescue operations, camping trips and outdoor expeditions. With its lightweight properties, it can easily be carried wherever you go without adding too much bulk or weight to your gear bag, and as it is highly durable, it won’t break or tear even after many uses over time. Specifically, you can use a kinetic rope for:

- Creating tension structures, such as hammocks and tents, when used correctly with the proper hardware.

- Construction of bridges, towers and buildings as it is strong enough to support large amounts of weight and remain flexible, making it perfect for projects that require stability over long periods.

- Sailing, as a kinetic rope, is lightweight and highly resistant to water damage. It does not shrink or expand when exposed to saltwater, making it ideal for marine applications such as boat mooring ropes and sail ties.

- Various climbing activities, including mountaineering, rock climbing, rappelling and ice climbing. Its strength makes it suitable for these activities without being too bulky or heavy, while its flexibility allows you to move around quickly while on the wall or cliff face.

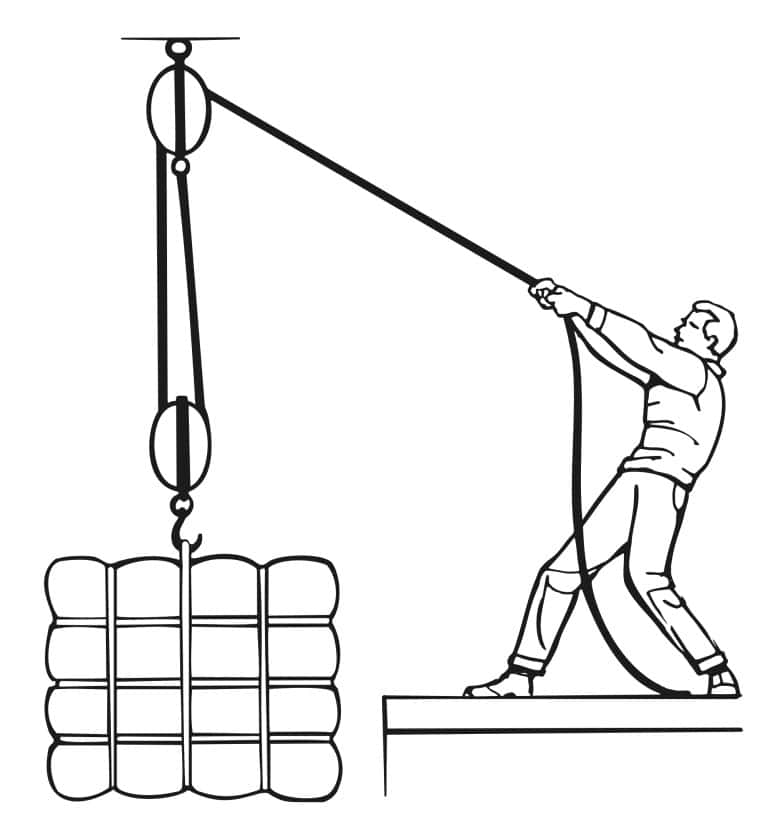

- Rescue operations to rescue people in distress, as it can hold up to heavy weights for an extended period of time.

- Zip lines as the rope is lightweight and robust, this ensures riders stay safe yet have plenty of fun during their ride down the line!

- Setting up tarps and shelters when camping.

- Making furniture and art projects as the strength of a kinetic rope makes it suitable for intricate designs that require stability, while its flexibility allows the artist to manipulate it into any shape they desire.

- Recovery of vehicles stuck or in precarious positions as the rope will stretch utilizing kinetic energy to smoothly transfer the pull between a recovering vehicle to a stuck vehicle. When used correctly, a kinetic rope stretches 20% and up to 30% at its breaking point.

- Rigging in sailing, parachuting, kite flying and other extreme sports, as a kinetic rope provides the tension needed to launch or land safely without breaking or stretching when put under pressure.

- Theatre productions to set up elaborate sets, props and action sequences on stage without compromising safety or stability.

Strength Of Kinetic Vs. Traditional Rope

A rope’s strength is measured by its tensile strength, the load at which a new rope, tested under laboratory conditions, can be expected to break. However, it is essential to remember that actual load levels in everyday applications can vary significantly from this theoretical value, so it’s always best to have a rope with greater tensile strength than you require.

For instance, if you are rappelling with a rope that has a tensile strength of 8,000 pounds, you should only apply up to 4,000 pounds of force to the rope. The same principle applies to other activities, such as arborist work or rescue operations where extreme forces may be applied to the rope, even if the tensile strength rating is high enough for the application.

Different types of ropes have different tensile strengths. For example, synthetic ropes tend to have higher tensile strengths than natural fibre ropes because synthetic ropes are usually manufactured in a controlled environment and designed with more specific properties than natural fibres, which are subject to environmental variations.

Finally, it’s important to remember that tensile strength is not the only factor in determining the overall strength of a rope. Other factors such as knot strength, UV resistance, abrasion resistance and material stretchiness also play an essential role in ensuring any rope’s strength and safe use.

Regarding rope strength, kinetic ropes come out on top over traditional ropes as they are made of fibres that contract and expand with each movement, which means they can hold more weight before breaking. On the other hand, traditional ropes are made of thicker strands that expand and contract very little but have excellent durability. Traditional ropes are less reliable in extreme weather conditions or under pressure, so kinetic ropes are usually better for these applications.

When kinetic rope begins to wear, tiny fibres slowly release their energy, and you will see hair-like fractures in the threads, but the rope is still viable though it needs to be used with caution. While traditional ropes are also made up of tiny fibres, when they show wear, they are more brittle, meaning that the rope’s lifespan is done as the fibres will break, meaning your rope will fail.

Traditional ropes are less expensive than kinetic ropes, but they don’t last as long and may not withstand heavy use. That said, kinetic ropes can not be coiled as tightly as traditional ropes, so store them neatly when not in use. As for lifespan, traditional ropes typically last around 10-12 years, but kinetic ropes can last up to 100,000 uses.

Buying Kinetic Rope

When shopping for kinetic rope, consider the following factors:

1. Memory curve

The memory curve is the most crucial factor when selecting a rope for any application. This curve describes how much it will stretch and rebound under different loads, which can be extremely useful in predicting how it will react to varying forces. The memory curve determines a rope’s fitness level, and a low memory curve means that the rope will have consistent performance over time. The kinetic rope memory curve is not the same as tensile strength.

2. Tensile strength

Tensile strength refers to how much tension a material can withstand before breaking or slipping out of place. While understanding a kinetic rope’s memory curve is vital in predicting its reaction to varying forces, it is equally as essential to consider the tensile strength of any rope when selecting one for an application. By understanding both metrics, you can be sure that your rope will have the best possible performance. Head over to our guide the Strongest and Weakest Types Of Rope to see the strength of various rope fibers.

3. Size and weight

The size and weight of the rope should be appropriate for the application. You can purchase kinetic rope in different diameters, and the diameter of the rope will play a factor in the rope’s tensile strength or the point where the rope will break as well as how heavy it will be. Choose a kinetic rope with two to three times the power you need to ensure you have the strength required for your application.

For example, if you are looking to hold up a theatre production cutout that weighs 600 lbs./272 kgs. multiply the weight by 3.0 (600 lbs. x 3.0 = 1,800 lbs.) You would then need a rope with a tensile strength of 1,800 lbs./816.5 kgs., which would be approximately 5/8 in./1.5 cm. in diameter.

4. Other features

Some kinetic ropes have additional ultraviolet coatings, waterproofing, attachments or grip enhancers added to the outer rope casing.

5. Cost

Like all things in life, the more bells and whistles, the greater the cost and kinetic ropes are no exception. The fibres, coatings, and attachments will increase the price of a kinetic rope. However, the most critical aspect is ensuring you have a rope that can handle the weight of your application.

Below are a few kinetic ropes for your application consideration

Whether you take your vehicle, quad, snow mobile or truck out into the elements this kinetic rope will provide you with the added security and ability to get out of any tough situation you may be stuck in.

The best single climbing rope diameter is between 9.0 and 10 mm (.35-.39 inches). A 9mm kinetic rope has a tensile strength of approximately 1900 kgs or 4,188 lbs. For beginners, a thicker rope is suggested, as a thicker rope offers greater abrasion resistance and is easier to handle. However, thinner ropes are better for advanced climbers as there is less rope drag, and the rope is lighter.

Whether you want to tie up heavy theatre props, or hang up a tarp when camping this rope will ensure you do so safely as long as your load does not exceed 7000 lbs.

Frequently Asked Questions

What are the benefits of using a kinetic rope for training and climbing purposes?

Kinetic rope sets are known for their increased safety and dynamic nature. They are made to absorb the force of a fall and reduce impact injuries. Additionally, kinetic ropes are more durable and require less maintenance than traditional ropes.

If I double up a piece of rope, will the rope strength be doubled?

No, doubling up the rope does not double its tensile strength. While it will make the rope thicker and thus more challenging to break, the tensile strength rating of a doubled-up rope remains the same as that of an individual piece. Therefore, if you want to increase your safety margin when using a rope, it’s best to get one with an appropriate tensile strength based on what activities you’ll be engaging in.

Which one should I use: kinetic rope or regular ropes?

When selecting a rope, consider the activity and the environment in which you will use it. For example, a kinetic rope is ideal for rock climbing because it stretches and absorbs shock and is also stronger and more durable than traditional ropes. However, traditional ropes are better suited for activities like sailing and rappelling because they offer more flexibility and are less likely to kink or tangle.

Final Thoughts

Traditional ropes offer some advantages depending on the application, but overall kinetic rope is lightweight and offers the best strength, durability, and flexibility, making it the perfect option when you need a reliable rope.